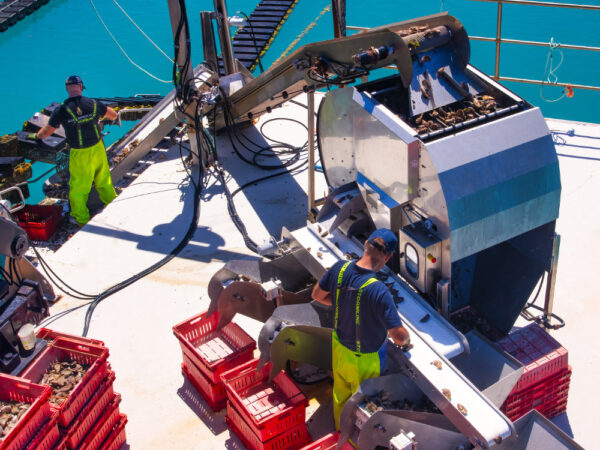

Sorting

The FlipFarm oyster sorter is a breakthrough in the efficient and effective processing of oysters. Sorting is one of the four important farming tasks of the FlipFarm system.

One pass does it all

A four way grade provides excellent classification of oysters from 10mm to 120mm shell length. Sorting belts can be swapped in minutes and the design has been specially developed for long service life and ease of maintenance.

Oysters are processed through the sorter and the timer controlled dosing hoppers deliver oysters into bulk storage, baskets or small crates suitable for operation with the FlipFarm filling station.

Full control of the rock'n'roll!

The shaker is fully controllable so that oysters can be handled gently to retain frill or more aggressively to shape and prune the growing edge.

The gentle shaking action is only required to settle oysters into the sorting holes. Movement of the oysters through the sorter is controlled by the rotating, self-cleaning belts.

Impressive throughput

The speed and capacity of the FlipFarm sorter is staggering. When sorting 20 to 50mm juvenile oysters up to 1.5 million oysters per hour can be smoothly and gently sorted into 4 grade classes. Feeding directly from FlipFarm baskets is possible at full speed allowing up to 1000 baskets per hour to be processed.